Here you will find the step by step installation instructions for the TuneRS Direct Oil Feed (DOF) kits version DOF1 (early 97 – 05 models) and DOF2 (late style 05 – 08 models).

TuneRS recommends professional installation for the Direct Oil Feed Kit. TuneRS takes no responsibility for improper installation of the kit. Take all precautionary safety measures. Please read through the complete instructions to familiarize yourself with the process before you attempt to do it for the first time. If you have any questions or are unfamiliar with the DOF or any IMS work, please contact us or one of your local professional installers. Failure to follow instructions properly may result in damage.

Tools & Equipment Required For DOF Installation:

- Auto Lift

- Air/electric grinder with bit (or hand saw and assortment of files)

- Flat-blade screwdrivers

- Flat-bladed pry bars

- Selection of sockets including 32 mm for chain tensioner

- Selection of wrenches

- Hex allen wrench for oil plug

- Spring-clip (c-clip) removal/insertion pliers

- IMS bearing extraction tool (if replacing the existing bearing)

- IMS bearing insertion tool (if replacing the existing bearing)

- Soft-faced mallet/hammer

- Grease

- Work gloves

- Rags/paper towels

- Engine oil catch can

Selecting The Right DOF Upgrade Kit

Here are the DOF Upgrade Kits To Choose From:

- The DOF Kit 1 is for M96 Porsche engines with the dual-row or single-row IMS bearing.

- The DOF Kit 2 is for M97 Porsche engines with the larger updated IMS bearing.

After 2006, engines replaced or rebuilt on 1997 – 2005 Porsche models by Porsche directly may have the larger updated IMS bearing which will require the TRS-DOF-0508 (DOF2) kit.

**IMPORTANT NOTES FOR TRS-DOF-9705 KIT (DOF1) INSTALLATION**

Previous versions of our DOF1 kits were supplied with two spacer rings. Newer versions (June 2015+) have one spacer ring for Single Row bearing installations only. Do not attempt to install the spacer ring for a Dual Row bearing or improper fitment & damage will occur.

**IMPORTANT UPDATE BEGINNING JANUARY 2021 ON DOF1 INSTALLATION**

The Direct Oil Feed kit now has an updated shaft bolt; it is larger in diameter. We have done this due to customers starting to run over 8000+rpm and high horsepower on their M96 engines for reliability purposes. All kits starting January 2021 will have this.

If you are an authorized installation shop and have an IMS bearing tool kit, you will need to modify the existing aluminum cylinder insertion tool to allow the larger shaft bolt to fit. Simply drill your existing tool component to the larger diameter of 13mm. If you are a DIY customer and purchased or rented the tool kit from us, the specific tool has already been modified for this.

Parts included in each kit:

- Patented DOF flange housing with 3 ribbed seal

- M14x1.5 (19 mm hex) oil line adapter with crush washer

- Oil line straight fitting with o-ring

- Tube of thread lock

- 3 new M6x20 micro-encapsulated flange housing bolts

- High-pressure flexible oil line (3,000 psi rated DOT)

- Camshaft housing plugs (qty 2)

- IMS bearing support shaft with nut and o-ring seal (for early single/dual row bearings)

- Retaining clip for IMS bearing (early single/dual row)

- Spacer ring for early single row bearings

Cars with the double-row bearing use the circlip provided & have no spacer ring required.

Cars with the single-row bearing use the spacer ring & circlip provided with the bearing.

Determining The Correct Bearing

Before you order your DOF kit, make sure to determine which type of IMS bearing is equipped on your Porsche. There is no 100% way to know what bearing type you have and the only accurate way to know is to already have access to your IMS flange (transmission removed). If you already know what bearing your Porsche model is equipped with and need to order a kit please give us a call.

- 1997 – 2000 Porsche Boxster and Carrera models will have dual row.

- 2001 – 2004 Porsche Boxster and Carrera models will have single row.

- Some early production 2005 models have also had the single row style equipped.

- 2005 – 2008 Porsche Boxster, Cayman and Carrera models are equipped with the larger style bearing that is not extractable

Identifying your bearing by the IMS flange:

- The dual row bearing will have a shallow flange

- The single row bearing will have a deep flange

- The later style larger bearing will have a shallow flange with a larger nut.

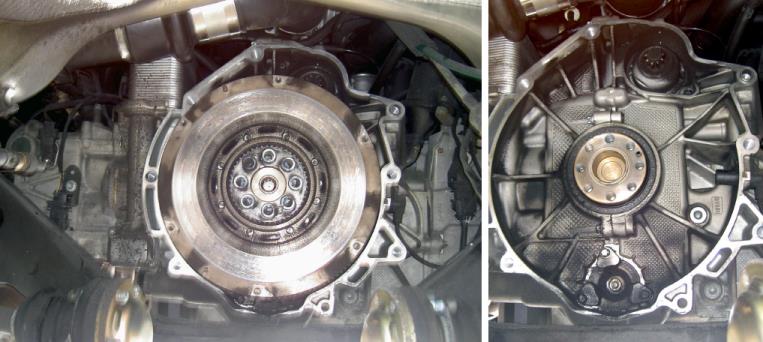

IMS Engine Flange Comparisons

It is very important that before proceeding with any IMSB replacement that you first inspect your engine. Remove the engine oil pan cover to inspect for any debris. At this time it is also a good idea to clean the oil pickup tube. If you have found any metal shavings or fragments, do not continue further as internal engine damage is already present. We also recommend to remove the engine oil filter and open it to inspect for any metal debris. Again, if any debris is found do not move forward.

INSTALLATION INSTRUCTIONS:

These instructions begin after the shop has removed the transmission from the vehicle according to Porsche’s recommendations. Perform this at your own risk.

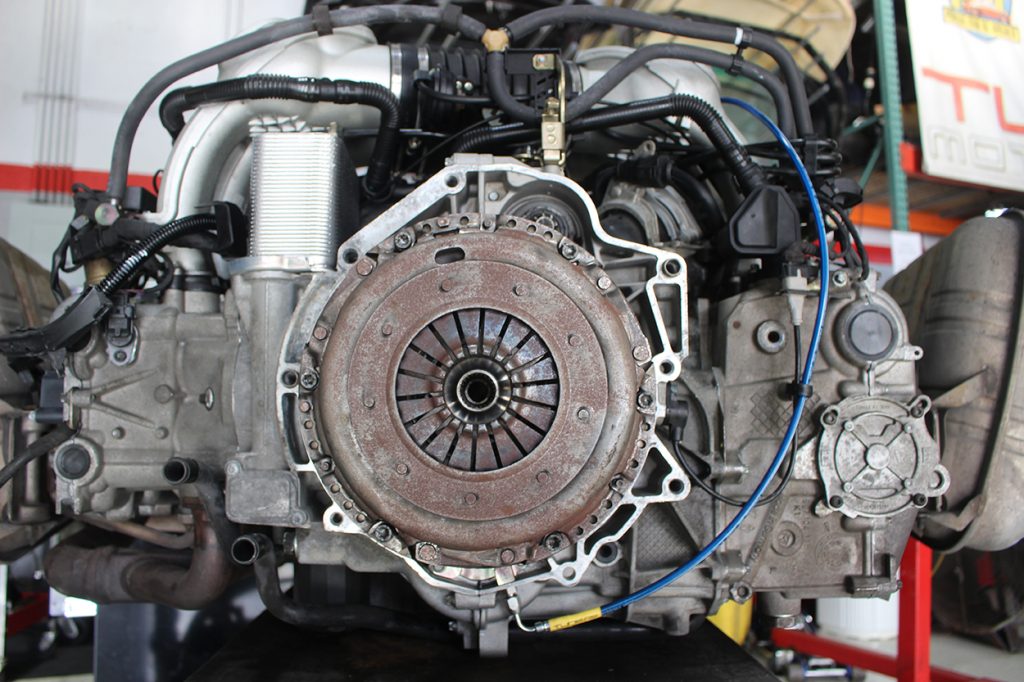

Step 1: Remove the clutch assembly (or torque converter).

Step 2: Remove the dual-mass flywheel.

Inspect the rear main seal (RMS) and determine if it will be replaced due to leaks. If replacement is needed, do so after the DOF installation. We highly recommend replacing the RMS at the same time as the labor to access is already being performed. We recommend using the original Porsche rear main seal.

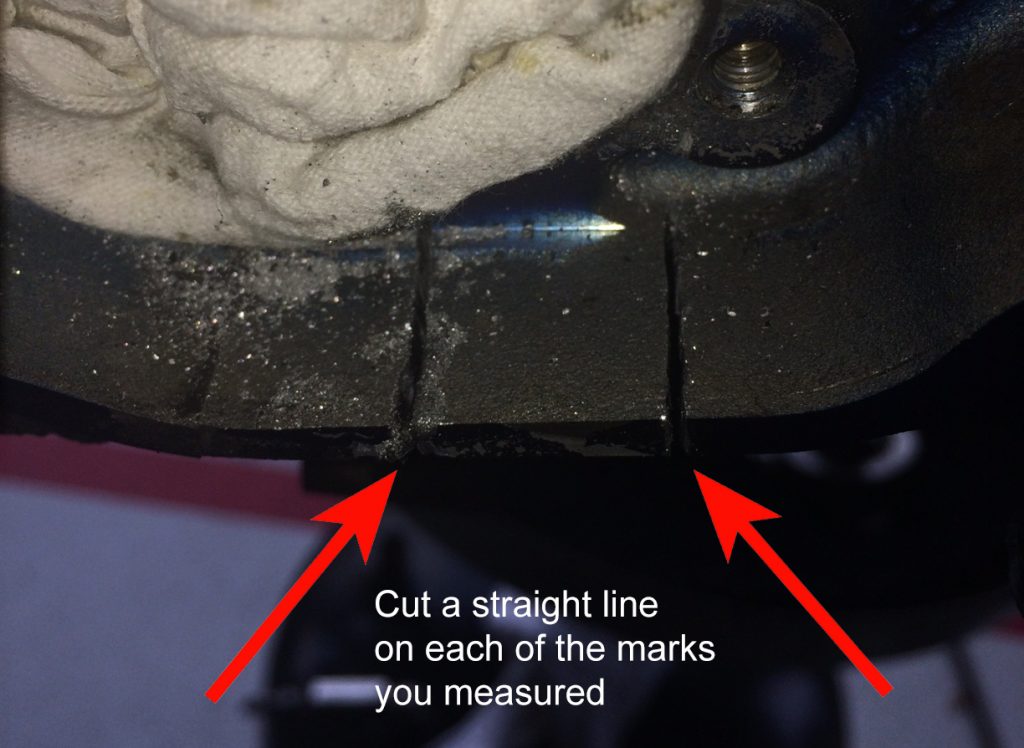

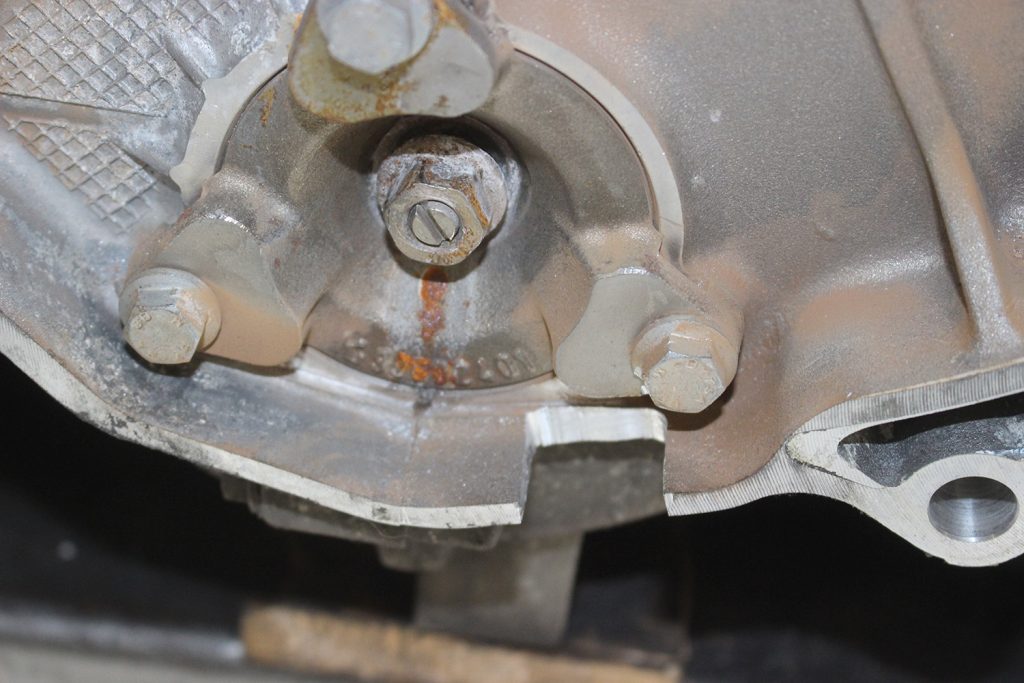

Step 3: Using a straight ruler or caliper and marker, on the bottom of the exposed bell housing edge on the engine, from the center, just under the IMS bearing, measure and place a mark at 17 mm and a second mark at 34 mm to the right of the center (as you’re looking at it).

Step 4: Clean the surrounding area of soot and debris.

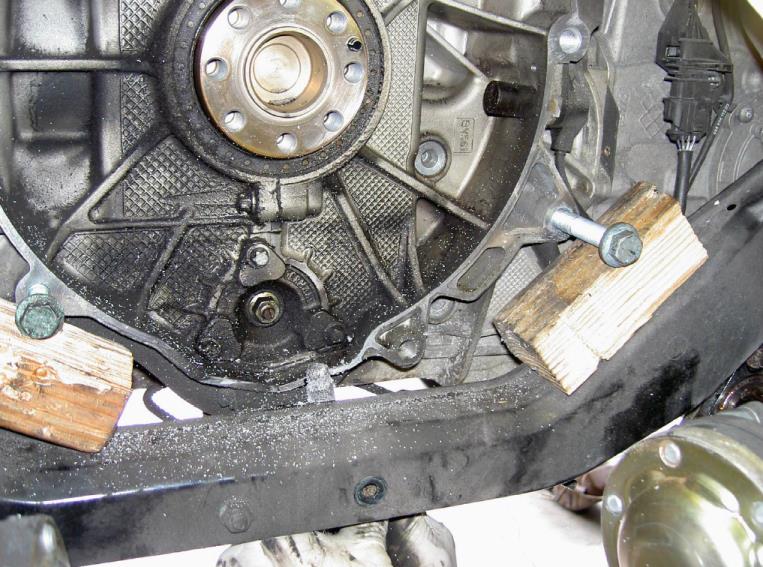

Step 5: To allow you more working room, on the Boxsters remove the side of the engine’s lower safety cable from the engine support yolk immediately under where you will be grinding into the bell housing. On the Carreras, loosen and move out of the way the rear sway bar.

Step 6: Using an electric or air grinder and correct bit for soft metal and/or a hand saw, cut at the measured marks on the bell housing edge. Cut all the way through the bell housing nerve up to but not into the engine case. It is important that you do this step BEFORE removing the flange – this will prevent any possibility of metal shavings getting into the engine. This process can be messy. Make sure to wear the proper eye protection as well.

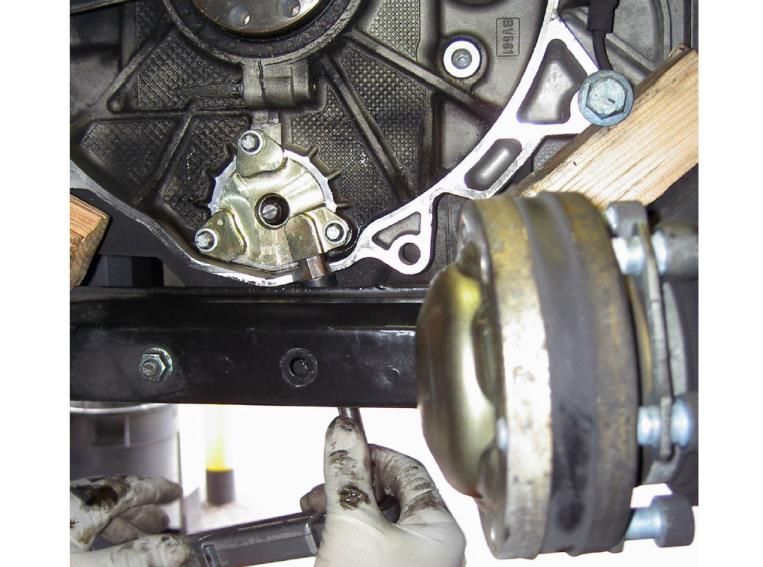

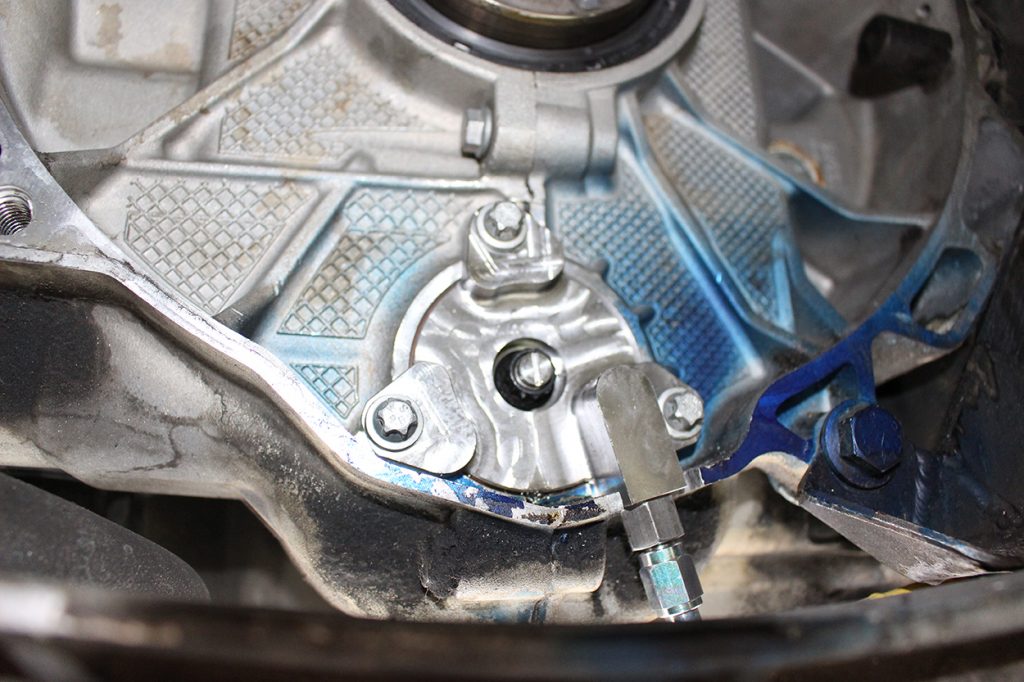

Once you have made your two initial cuts (shown above), use an adjustable wrench to grab the newly created “tab” to break the piece off.

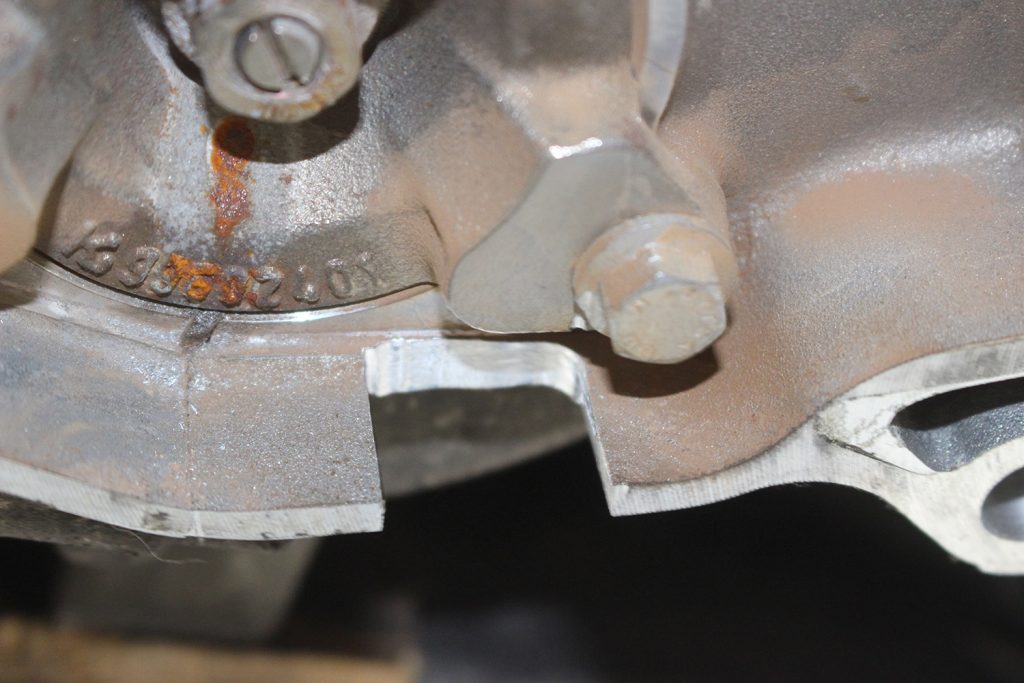

This is the result of the notch that has been created. Once you are here, you will need to finish the notch by using a file or dremel to clean the edges.

Step 7: Clean all of the metal debris.

This is how the final notch should look after you have done your measuring and cutting. Use a file to clean the edges.

Step 8: Put the engine in top dead center (TDC). Lock camshaft on cylinder bank 1-3. On the Boxsters/Caymans, remove the right camshaft plug and lock cam in place with the correct locking key. On the Carrera it’s the left camshaft.

Step 9: Also, lock the engine’s crankshaft to avoid any movement during installation.

Step 10: Drain the engine oil.

Chain tensioner removal

Step 11: Using a 32 mm socket, remove the bank 1-3 chain tensioner (on the Boxster the right / on the Carrera the left). Be prepared to catch oil. You will also need to remove the primary chain tensioner. Be prepared to catch oil. After chain tensioner removal, the crankshaft must NOT be turned under any circumstances otherwise the timing chain may jump over.

Now begins the Flange & Bearing removal steps

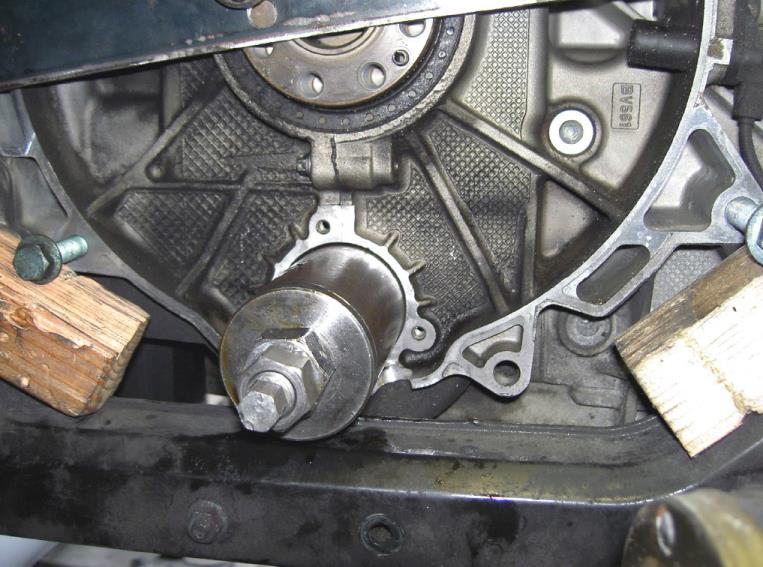

Step 12: Holding the end of the bearing support shaft with a flat screwdriver, loosen and remove the center nut.

Step 13: Remove the three flange support bolts.

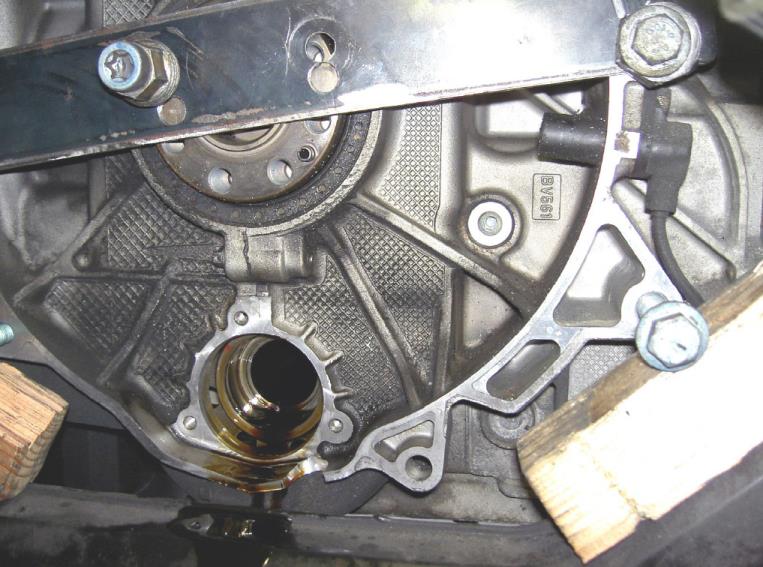

Step 14: Using a couple of flat-bladed pry bars or strong screwdrivers slowly and carefully pry out the existing bearing flange. Be prepared to catch oil.

NOTE:

On the later style larger bearings (non extraction), simply remove the outer seal of the IMS bearing. Skip the steps below showing “IMS bearing removal/install” as this does not apply

to you.

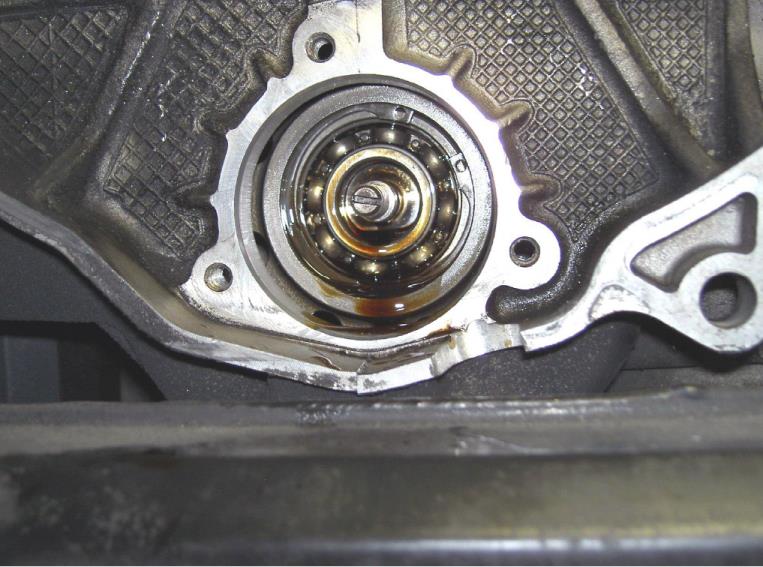

Step 15: Test to see if there is any movement (slop) in the bearing’s shaft. Lateral movement (slop) means that the bearing has started to wear down.

NOTE: If installing the TRS-DOF-9705 (DOF1) kits with either a dual row or single row bearing, you MUST use the bearing that was purchased with the DOF kit for your vehicle. Other aftermarket bearings such as ceramic or roller will not fit with the custom DOF flange and if another brand & style of bearing is used with the DOF other than what was supplied damage will occur due to improper fitment and we take no responsibility for incorrect installation.

Step 16: On the later style Boxster / Cayman / Carrera (MY 2005 – 2008) or vehicles equipped with replacement Porsche engines after 2006 that have the larger IMS bearing that cannot be extracted, simply remove the outer seal of the exposed IMS bearing. Failure to remove the outer seal will warrant the DOF kit useless as the filtered & cooled oil will not be able to contact the ball bearing.

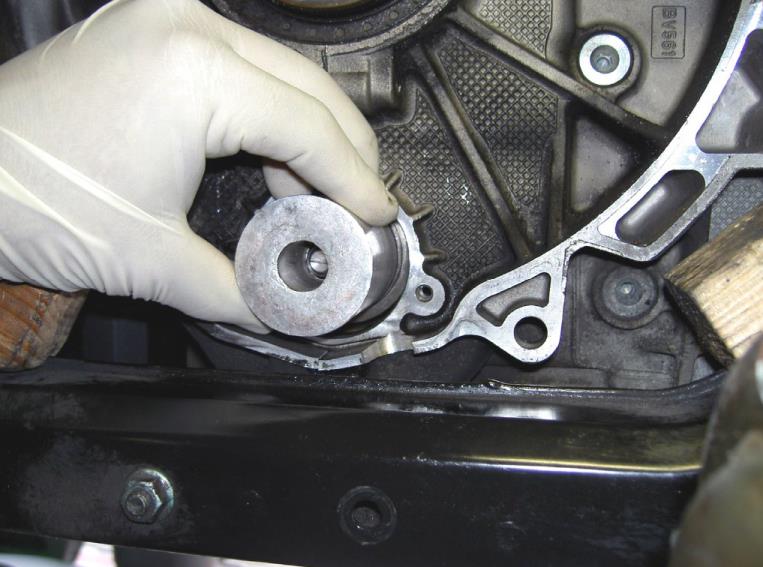

Step 17: With the IMS bearing exposed, remove the retaining clip. This step does not apply to 997/987 with larger IMS bearing.

Step 18: Screw the center bolt from the bearing removal tool onto the bearing’s support shaft and tighten by hand.

Step 19: Place the bearing removal tool onto the center bolt and tighten the main nut by hand so that the tool is completely against the engine case.

Step 20: With a wrench, hold the center bolt so it doesn’t rotate and start tightening the main nut slowly. At some point you may hear a loud pop which is normal. Keep tightening the main nut until the bearing is completely removed. The bearing will come out inside the removal tool. Be prepared to catch oil.

Step 21: Clean out the open end of the IMS. Leave a thin film of oil or grease so that the new bearing slides in easier.

Steps to prepare and install the new IMS bearing

Here is how your new SKF steel IMS bearing should have arrived, packaged with the correct spacer ring and clip. These bearings are made to work with our DOF flange.

(DS = Dual steel)

(SS = Single steel)

UPDATE AS OF JANUARY 2021

The Direct Oil Feed kit now has an updated shaft bolt; it is larger in diameter. We have done this due to customers starting to run over 8000+rpm and high horsepower on their M96 engines for reliability purposes. All kits starting January 2021 will have this.

THE UPDATED TORQUE ON THE CENTER NUT FOR THE DOF1 SHAFT BOLT IS 18ft/lbs

Step 22: Place the new bearing support shaft onto the new bearing. Make sure that the open side of the bearing faces towards the shaft’s threaded end.

Step 23: Place the bearing with the shaft in place over a socket of the correct size which can support the inner race of the bearing and lightly tap the end of the shaft completely onto the bearing’s inner race.

Step 24: Place the assembly into the bearing insertion tool.

Step 25: Carefully center over the bearing’s seat.

Step 26: Tap the end of the insertion tool until the bearing is seated completely. You will hear a “solid” change in sound when the bearing has reached the engine block.

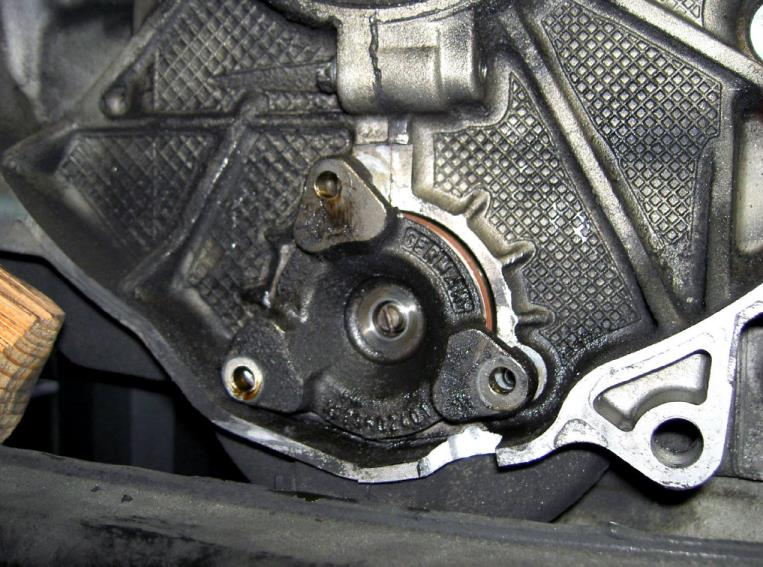

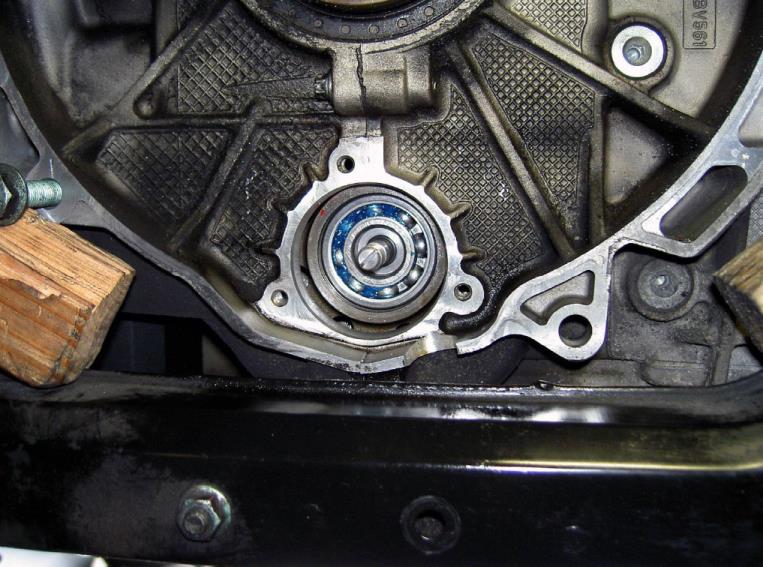

Step 27: Pull the insertion tool out. The correctly installed bearing should look like this:

Step 28: Using the proper C-clip pliers insert the new retaining clip (supplied).

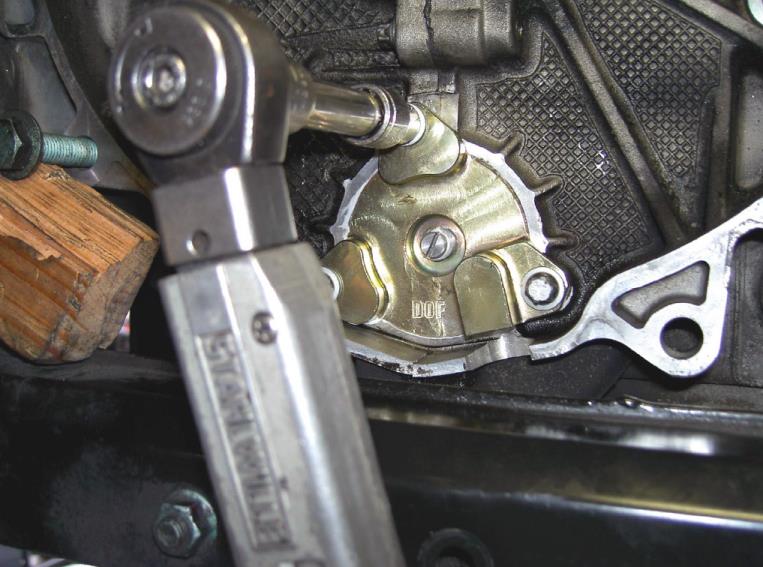

Steps to prepare and install the DOF flange

Step 29: Insert the spacer ring (supplied) onto the DOF (only if single row bearing is being installed. Dual row does not have spacer). **Most of the early DOF kits prior to June 2015 had a spacer for both dual and single row. These kits are no longer in supply and the newer version is now supplied with only 1 spacer ring for the single row IMS bearing. If you have any questions contact us before proceeding.

Step 30: Smear a bit of high-quality white lithium grease on the inside of the DOF shaft and on the outside red sealing ring.

Step 31: Place the new DOF flange with spacer ring in place onto the bearing support shaft.

Step 32: Thread one of the old, removed bolts in place on the top most hole of the flange. Insert a phillips screwdriver or punch-pin into one of the two remaining holes and carefully use as a lever to gently guide the flange into position. Once in position, using the butt end of a hammer’s wooden handle or a soft-faced mallet, tap the flange into place. Remove the old bolt.

Step 33: Check the clearance for the DOF/Oil line screw-in adapter on the bell housing cut-out that you made before. Adjust the clearance if necessary with a file.

Step 34: Insert the three new, micro-encapsulated flange bolts (supplied) and thread by hand.

Step 35: Tighten each bolt only a few turns at a time and move to the next one. This assures that the flange gets inserted correctly.

Step 36: Once all three bolts are completely screwed in and the flange has been seated, tighten to a torque of 10 Nm (7.5 lb-ft or 88.5 lb-in).

Step 37: Put a bit of thread locker (supplied) onto the threads of the new bearing support flange nut (supplied) and thread in place by hand.

DOF1 center nut torque – 15 Nm (11 lb-ft or 132 lb-in)

THE UPDATED TORQUE ON THE CENTER NUT FOR THE DOF1 SHAFT BOLT IS 18 lb-ft. IF YOU HAVE THE LATEST UPDATED DOF1 KIT PLEASE MAKE SURE TO FOLLOW THIS NEW TORQUE.

DOF2 center nut torque – 19 Nm (14 lb-ft or 168 lb-in)

Step 38: Put a bit of thread locker (supplied) onto the threads of the straight hose adapter on the O-ring side.

Step 39: Thread into place onto the DOF flange. Note that the o-ring end of the hose adapter screws into the DOF.

Tighten to a torque of 10 Nm.

Step 40: Clean the previously removed chain tensioner.

Step 41: Insert and tighten the chain tensioner.

Torque to 80 Nm (59 lb-ft).

Step 42: Remove the cam locking key and lightly tap the (supplied) green cam seal in place.

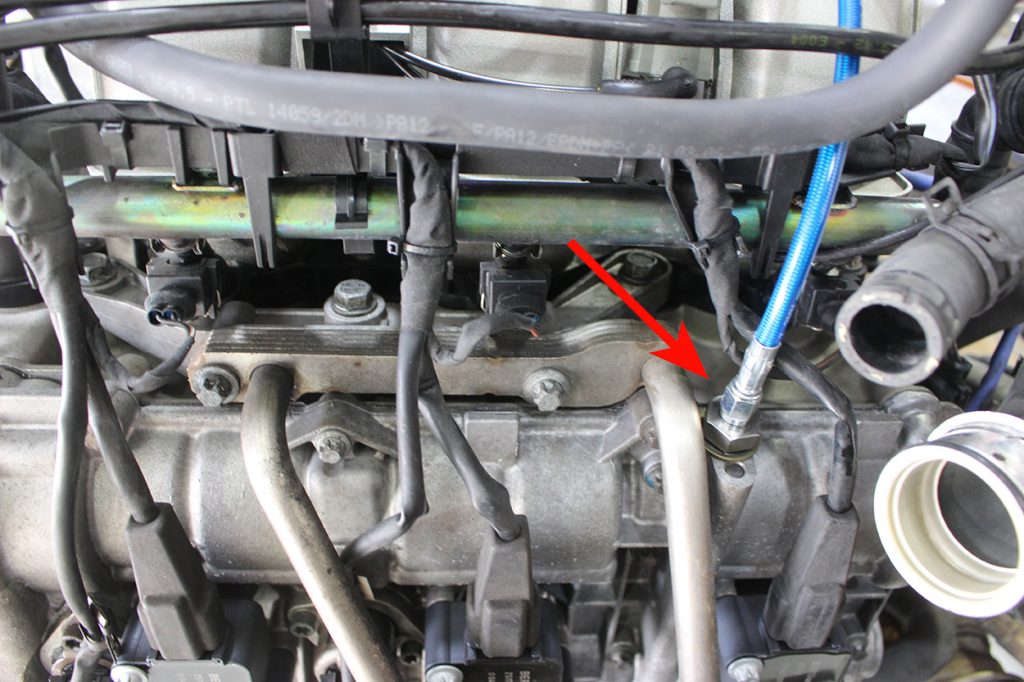

Step 43: From the top of the engine thread the angled end of the high pressure oil line down to the DOF and thread into place.

Torque to 13 Nm (10 lb-ft or 115 lb-in).

Step 44: On Boxsters replace the earlier removed engine safety cable to the engine support yolk and tighten. In the case of the Carrera, replace the rear sway bar and tighten.

NOTE: If you see the sway bar too close to the DOF fitting, this is an indicator that the motor mounts are worn and need to be replaced.

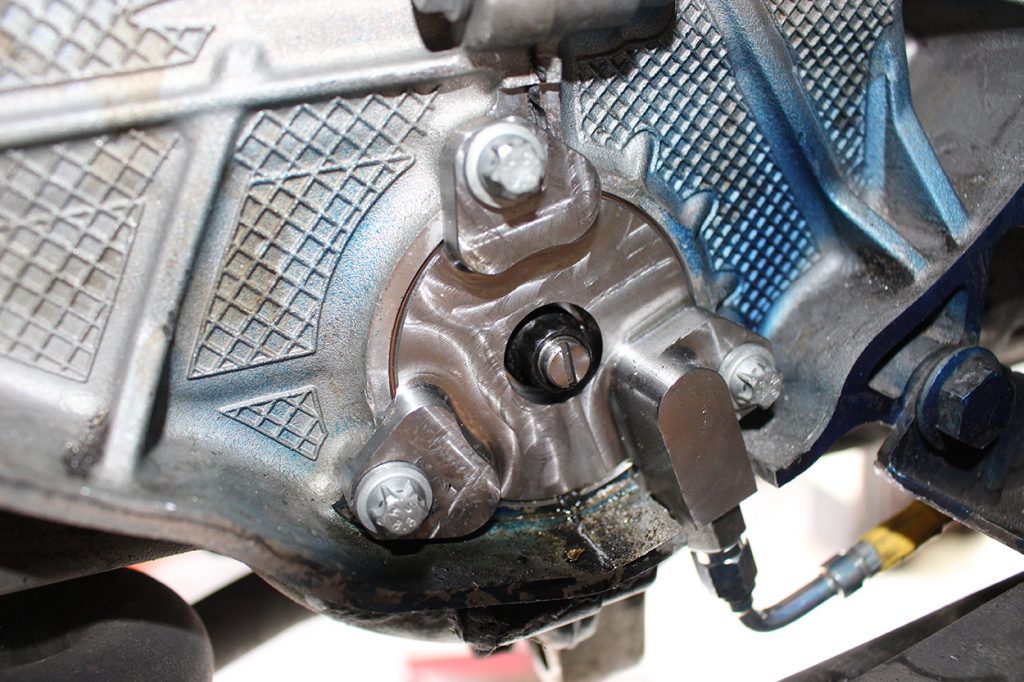

The two photos below show the DOF hose routing from the flange to the port on the cam cover.

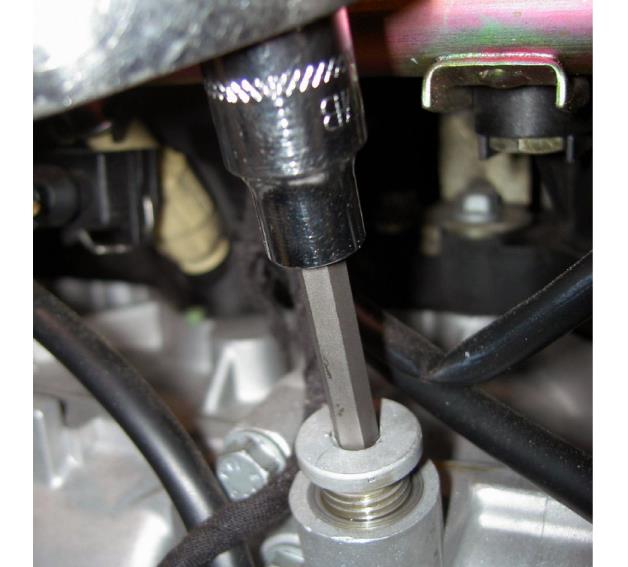

Step 45: Working from the top of the engine, remove the factory oil port plug on the left side of the top of the engine cam cover, next to the air filter box and under the rear end of the fuel injector bar (on the Boxster). The Carrera’s oil port will be on the front left side of the engine. If there is a sensor in this location, then use the port on the opposite side of the engine.

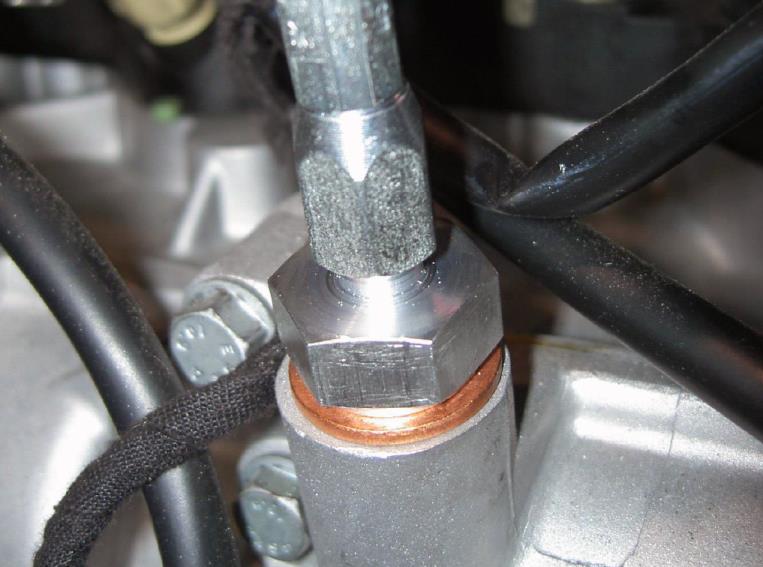

Step 46: Place the copper crush ring onto the 14 mm end of the hose adapter. The adapter should have already come with the crush washer installed to it (if not, ensure it is properly installed). Put a couple of drops of thread locker (supplied) and thread onto the engine.

Torque to 15 Nm (11 lb-ft or 132 lb-in).

Step 47: Finally thread the free end of the high pressure oil line onto the newly inserted adapter.

Torque to 13 Nm (10 lb-ft or 115 lb-in).

Step 48: Check to make sure that nothing is loose.

Step 49: If the Rear Main Seal is to be replaced, do it now. Follow the proper Porsche removal & insertion procedures for the rear main seal.

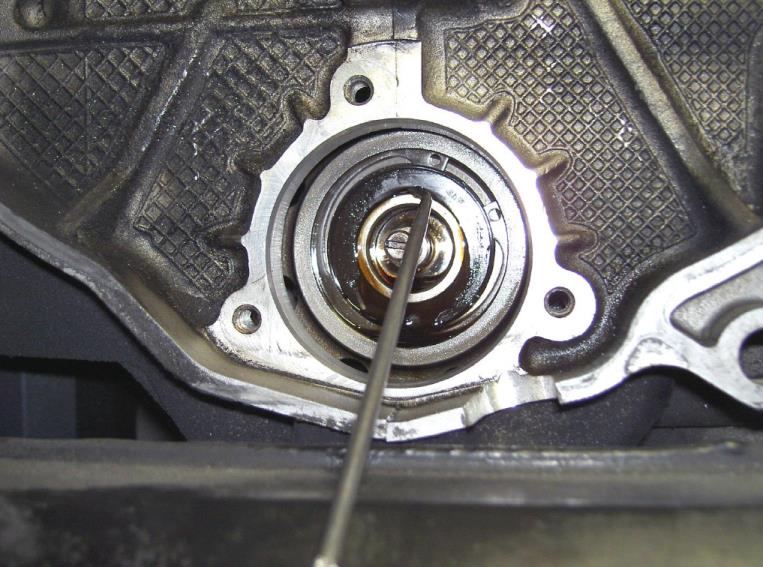

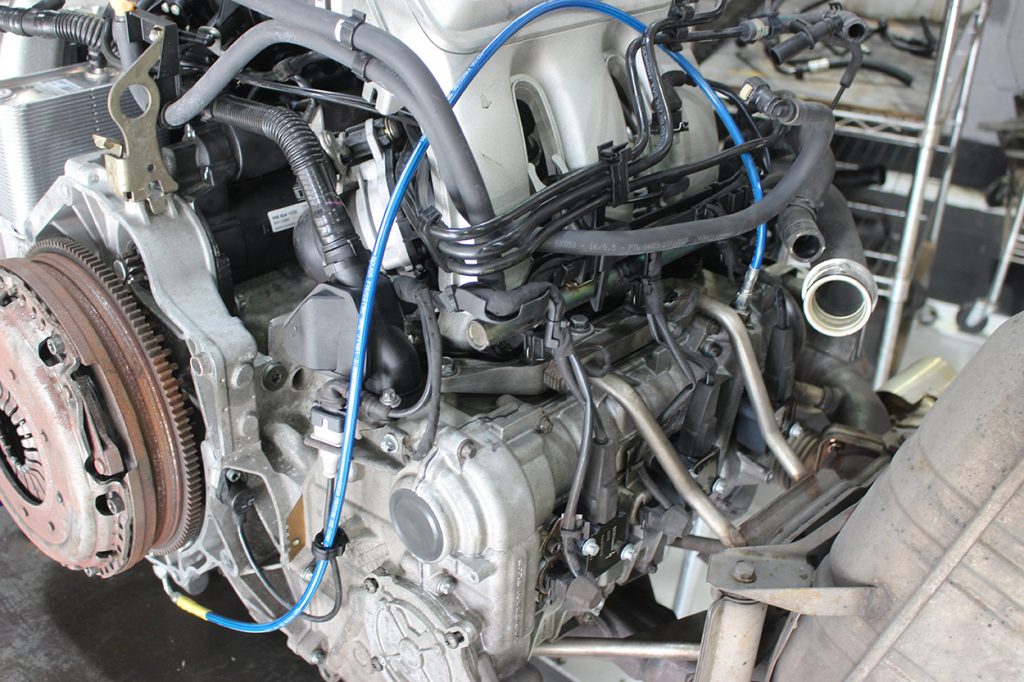

This is how your DOF kit should look installed once you have everything tightened up before installing the flywheel/torque converter/clutch/transmission.

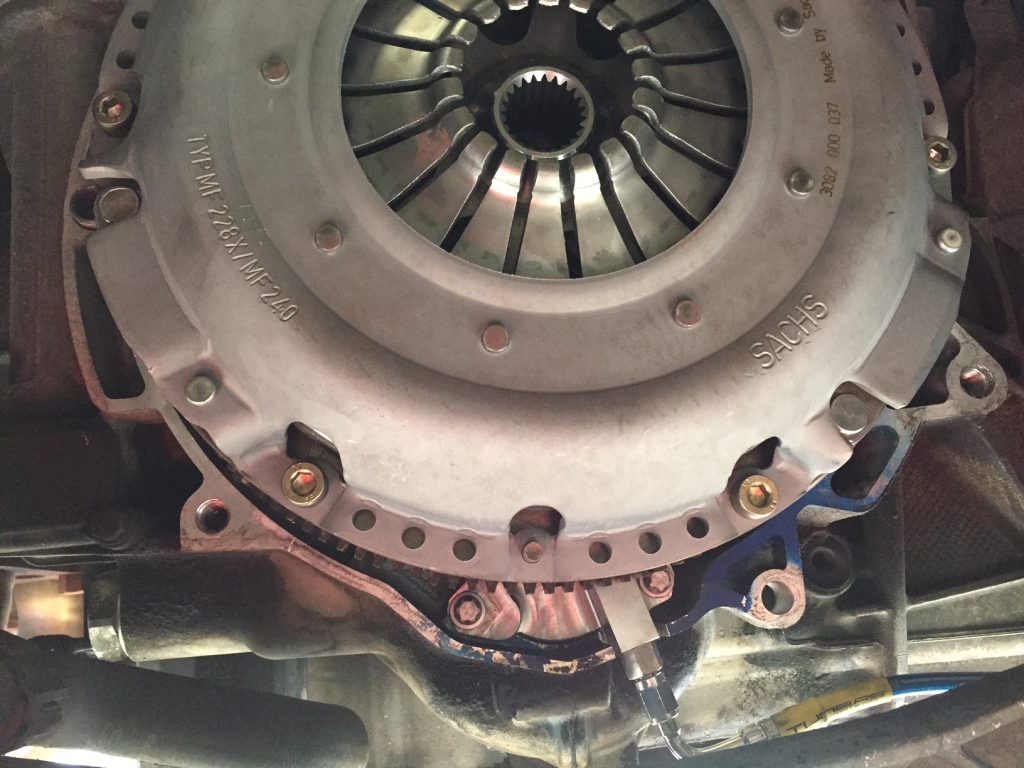

Step 50: Reinstall the dual-mass flywheel.

Step 51: Reinstall the Clutch/Torque Converter.

Step 52: Reinstall the Transmission.

Step 53: Reinstall all removed panels, plates, muffler etc.

Step 54: Install new engine oil filter and fill engine oil level with proper oil.

Step 55: Run the engine and make sure there are no leaks.

Step 56: Go out and enjoy your Porsche and drive with peace of mind!