Solve your IMS bearing’s cooling and lubrication problem!

U.S. Patent # 10,443,457

U.S. Patent # 10,858,973

While working on rebuilds for a number of water cooled Carreras and Boxsters around 2008 we noticed that the the much talked about culprit of many engine failures on Carreras, Boxsters and Caymans between 1997 and 2008 was not necessarily just the IMS or Intermediate Shaft Bearing. While some will argue about the bearing design itself, we noticed that the common issue for many engine failures was due to the sealed IMS bearing eventually losing it’s internal lubrication and the bearing requiring more lubrication and better cooling to help increase the bearings longevity, not the bearing itself. We found a simple solution that would solve this issue of lack of lubrication and cooling and began the development and testing of our patented Intermediate Shaft Bearing Direct Oil Feed System (DOF)® lubrication kit. The bearing is not the problem; it’s the lack of proper lubrication & cooling.

In 2009 Miguel (Mike) Potolicchio of TuneRS came up with the initial concept and invested much of his time and energy into designing, testing and developing the Direct Oil Feed (DOF)® lubrication system. Several vehicles were picked during the development stages and prototypes were installed, carefully studied and documented. The first prototype was installed in early 2010 on a 1998 Porsche Boxster street driven & lightly tracked vehicle. The first finalized, non-prototype DOF® was presented in early February at the 2013 PCA 48 Hours at Sebring. We placed this first finalized DOF® on our #93 Spec Boxster (build #001) for the 48 hour Sebring PCA club race event and documented the results (specifically oil pressure drops and other parameters) afterwards. Our analyses also determined that the oil fed to the ball bearings had cooled the bearing temperatures on an average of 30+ degrees Farenheit. After the success and interest at Sebring we began to offer our Direct Oil Feed System (DOF)® lubrication kit as a solution for all MY97-08 M96 and M97 Porsche engines with IMS bearings.

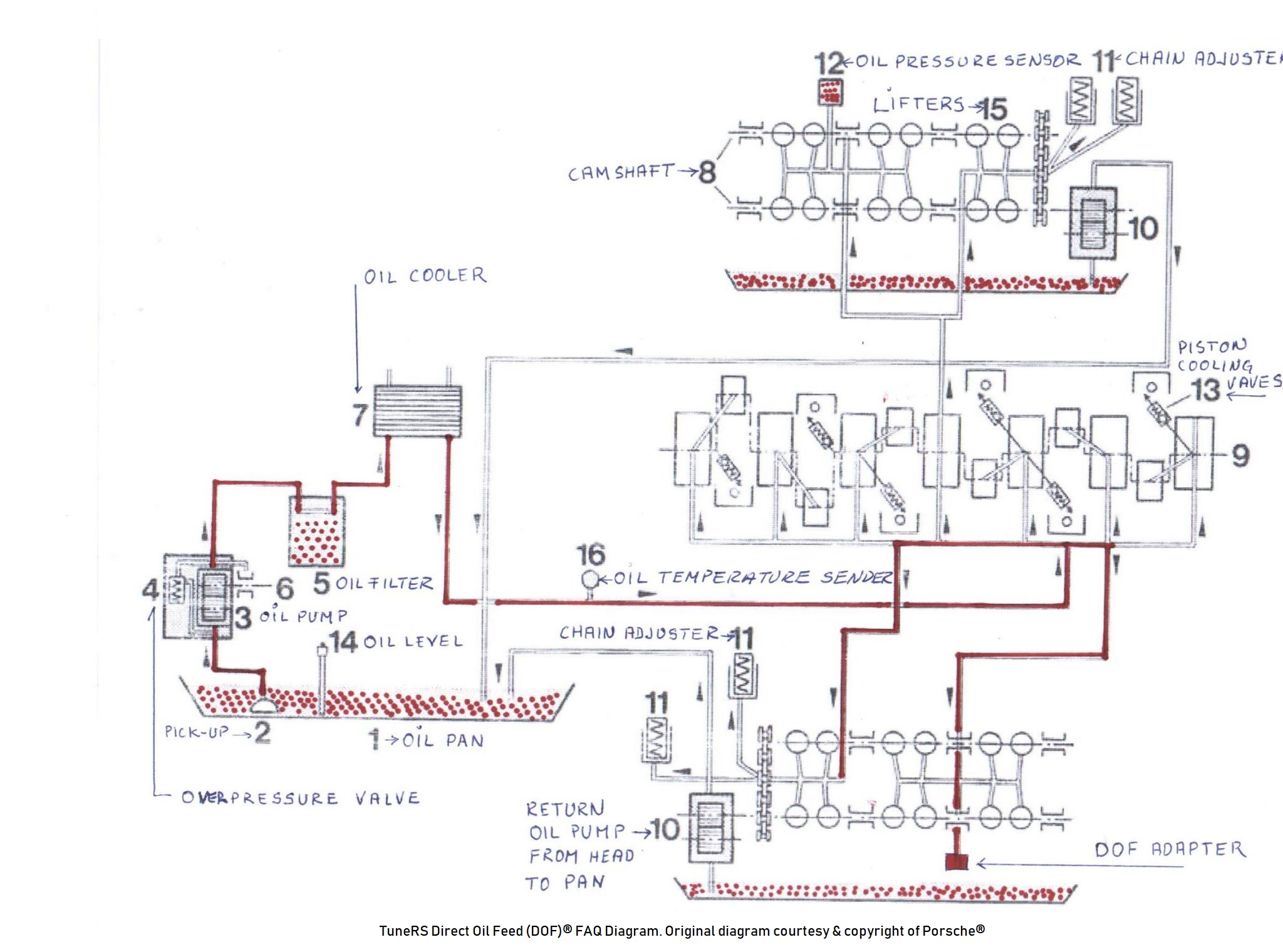

How Does TuneRS Direct Oil Feed (DOF)® Work?

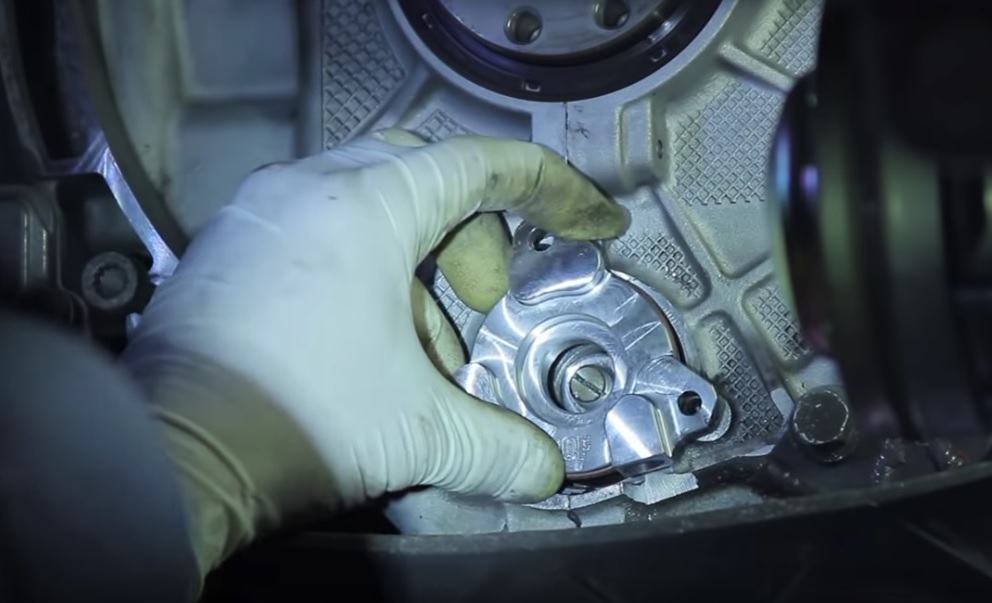

You are probably asking how does the TRS DOF work? TuneRS Direct Oil Feed (DOF)® kit uses a patented custom made Intermediate Shaft Flange that enables a direct flow of filtered and cooled motor oil directly to the open end of the Intermediate Shaft Bearing. The bearing receives oil fed by a custom oil line run from the positive oil pressure feed located on the engine valve cover directly to the custom designed Intermediate Shaft Flange. This oil comes directly after the oil cooler, thus delivering a cool flow of oil. This much needed lubrication & cooling has direct access to the ball bearings as the outer seal on the bearing is removed to allow the oil flow. Therefore providing the bearing with continuous flow of filtered engine oil for constant lubrication & cooling.

We Offer IMS Bearing DOF® For The Following Porsches:

- Porsche Boxster 986 MY 1997 – 2004

- Porsche Boxster 987 MY 2005 – 2008

- Porsche Cayman 987 MY 2006 – 2008

- Porsche 911 Carrera 996 MY 1998 – 2004

- Porsche 911 Carrera 997 MY 2005 – 2008

- Excludes Turbo, GT2, GT3 and DFI models

Street Reliability & Race Proven!

If a TuneRS race car is built with our Direct Oil Feed® then we think you will want it on your Porsche. The TuneRS DOF® kit also includes a purchase of a steel SKF bearing to replace your old IMS bearing that might as well be replaced to start with a fresh IMS bearing with zero miles and the now added benefit of the DOF® lubrication. Other options on the market such as roller thrust bearings especially need lubrication due to the large contact surface that increases heat and friction in roller bearings. Regardless of the bearing selected, it still requires lubrication & cooling for the bearing longevity.The TuneRS DOF® provides constant bearing lubrication & cooling to try to alleviate that risk and is an excellent way to protect and potentially add to the resale value of your Porsche.

FIND A LOCAL INSTALLER OR DISTRIBUTOR

While we have clients that bring their cars to us from outside of Florida, we understand not everybody can bring their cars to our shop. Therefore we have developed a global network of independent Porsche shops and Distributors to make our TRS Development parts more accessible to everyone.

DIY DIRECT OIL FEED

Are you a do it yourselfer? If you are a skilled DIYer and you have the equipment to perform the installation yourself then you can order your Direct Oil Feed kit online.

While we provide step by step instructions for installing your Direct Oil Feed® on your Porsche we suggest you consider whether you are equipped with the appropriate tools, time and mechanical inclination before taking on this project yourself. Some of our clients have performed this service themselves and we have complete faith in our customers. We encourage you to carefully review our installation guide first. If you are not sure about whether you can handle this yourself then we highly recommend you contact us at 954-345-7877 to make an appointment. If you are not anywhere near our facility in Coral Springs Florida and can not transport your car to us then we highly recommend you visit our list of reputable independent TRS installers and distributors.